|

Metallurgy:

(Prehistoric Evidence of...)

Metallurgy:

(Prehistoric Evidence of...)

|

A Chronology of Prehistoric Metallurgy: |

Metallurgy in Europe.

The Earliest Copper

Mining

Europe: (Vinca Culture, c. 5,000 BC).

The early Neolithic

mine of Rudna Glava near Majdanpek is an

example of the oldest known technology of Vinca copper working. The developed

skills of the Rudna Glava miners are indicated by the ore-emptied shafts no less than 20m deep.

Stone mallets, made from river stones

of volcanic rock, gives evidence of the higher

specialization of primitive tools for different and

various productive purposes. As for the chopping of the pieces

different types of wedges were used, while the tools made from

deer horns were used for gathering the ore already chopped.

When an ore vein was

discovered, the access platform was built round its flooding

canal. Afterwards the hard ore mass was broken into pieces by

circular hits with stone mallets, hanged either on a rope or leather

belt. In the depths, the technique of heating then cooling

suddenly was

used. Large ceramic dishes were used for

pouring the water over the hot ore blocks. Cracked blocks were

further smashed and broken into pieces.

The ore obtained was

taken to the surface in bags, and it was distributed to

the settlements near by. Further metallurgic processes are

considered to be a part of technological circle of handworks in

that early period of metal usage.

-

(Full Article:

http://www.muzej-mpek.org.yu/e_rglava.htm)

|

Article:

(Bulgaria

- c. 3,000 BC) - Thousands of uniformly 'pressed' gold 'beads'

were discovered in a Thracian horde in the Bulgarian 'Valley of the Kings'.

The beads, which are only millimetres in diameter, have the appearance of

minute 'washers', which show evidence of 'pressing' on both sides. The

amount discovered, and their uniformity, have led to the suggestion that

they were mass-manufactured, or machine made.

(Ref: UK Ch4 News 31.8.2005)

|

The first Metalworkers in

the UK - (4,000 BC - 2,000 BC) The New Scientist.

The following article questions the origin of the raw materials and science

used for the 'Copper-age' and 'Bronze-age' in ancient Britain.

Copper-arsenic alloys were used throughout mainland Europe and the Middle

East during the 'Copper Age', the slow transition from the late Neolithic to

the Bronze Age between about 4000 and 2500 BC. These prehistoric 'arsenical

coppers' span the period between the first smelting of copper and the

development of bronze, which is an alloy of copper and tin.

'Until recently most

archaeologists assumed that arsenical coppers were the first

intentionally produced alloys. Various arguments were put forward in

favour of this idea, stressing the advantages of arsenical copper

over pure copper as a material for making tools and weapons. The

arguments were based on some well-known facts about arsenic. For

example, it could act as a deoxidant in casting, preventing the

metal becoming too brittle, and it increased the hardness of edges

formed on tools and weapons by hammering.

There are various opinions

about which methods were used to introduce the arsenic, but by the

1970s most researchers believed that the arsenic was there because

Bronze Age metalworkers had selected copper ores that were naturally

rich in the element. Copper ore deposits are usually laid down in

rock fissures or veins as primary copper sulphide minerals. Exposed

areas of such deposits are converted to secondary minerals such as

oxides and carbonates. Within some primary copper deposits are the 'fahlerz'

ores, which contain arsenic and the metal antimony. The metalworkers

had apparently discovered that these ores yielded a superior

produc't.

When archaeologists

put metal artefacts in chronological order, they have always assumed

that as metals technology evolved, simple designs and materials would

gradually be replaced by more sophisticated and specialised ones.

Comparisons between such metalwork typologies for various parts of

Europe supported the diffusion hypothesis. They revealed that the pace

of metallurgical development varied greatly. Metals appeared later

in the archaeological record of north-western Europe than in the south

and east, for instance, and southern metal artefacts appeared to be

more advanced than northern European forms of the same age.

'While some archaeologists were

classifying metal artefacts by their physical appearance others

began to analyse their composition, especially after spectrographic

methods became widely available in the 1930s. This approach,

pioneered by the German chemists Helmut Witter and Wilhelm Otto and

the Austrian scientist Richard Pittioni, culminated in a massive

programme, based in Stuttgart, which was responsible for more than

16 000 analyses of Early Bronze Age metalwork by the mid-1970s'.

By then, metalwork

typologies for Britain were already well developed as were ideas,

partly based on them, about the origins of British metallurgy. The

appearance of metals in the archaeological record of the British Isles

was associated with other changes, particularly a shift in burial

practices and the appearance in graves of a new form of pottery,

shaped like a small cup or beaker. Archaeologists had found evidence

for similar changes in central Europe and Iberia at the beginning of

the Bronze Age, and it seemed likely that Britain was invaded and

settled by a new population from elsewhere in Europe, possibly the

Rhineland. It was these 'Beaker Culture' settlers who were thought

to have brought a knowledge of metals to Britain. Not only that,

but axes, by far the most common Early Bronze Age artefact, were

unevenly distributed across the British Isles: there are heavy

concentrations in Ireland, most of the earliest forms in the

south-western region of Munster. It seemed clear that metallurgy was

introduced to Britain via Ireland.

'Confirmation

that the earliest Irish Bronze Age tools were high in arsenic

was supported by findings of the same impurity pattern in the few

artefacts of this period found elsewhere in the British Isles. This

led him to the proposition that an Irish metal industry had existed,

supplying England, Scotland and Wales with copper during the

earliest Bronze Age, based on the exploitation of

fahlerz ores from

southwest Ireland. The high levels of arsenic in early bronzes in

Ireland and the rest of the British Isles indicated that the early

Irish industry had continued well into the Early Bronze Age. Only

later did centres of production develop outside Ireland; these made

more developed forms of flat axe in which the metal had different

impurity patterns, including relatively high levels of nickel'.

Although the significance of arsenical copper in

the earliest part of the Bronze Age is still disputed, it does seem

that arsenical copper was not intentionally produced in order to make

better tools. On the contrary, there is now a large body of evidence,

including the compositions of copper artefacts, to suggest that the

processes used to smelt the metal were very primitive, and may have

restricted early metalworkers to the use of particular types of ore

deposit.

Clearly, the technology was not

well developed and there is no reason why it should have been

introduced as a result of population movement. The fact that

accessible deposits of suitable minerals are far more widespread in

other parts of the British Isles than they are in Ireland makes one

suspicious of any suggestion that Britain's earliest metal

production was based exclusively there.

The article ends with the

following words...again raising more questions than answers...

'Of course, we can never be sure of

the sequence of events more than four thousand years ago which led to

the production of the first metal artefact in the British Isles. But I

am sure that Beaker Culture metallurgists from the Rhineland never

stalked the Munster (Irish) countryside in search of fahlerz

ores to make it'.

(Ref:

http://www.newscientist.com/article/)

Metallurgy in the Middle-east.

Having already mentioned that metals

appeared later in the archaeological record of north-western Europe than in the south and

east, and that southern metal artefacts appeared to be more advanced

than northern European forms of the same age, we can now support this with

earlier discoveries from the middle-east, as the following examples

demonstrate. It is a reasonable conclusion that European metallurgy had a

Middle-eastern origin...

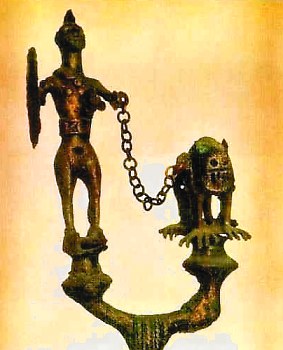

Metsamor (Medzamor),

Armenia

-

Metsamor has revealed foundries that were processing

metal as far back as 5,000 BC. The site contains the oldest large-scale

metallurgical factory in the world (2,500 BC). Discovered by Dr Koriun Megatchian, in Soviet Armenia (20Km from Ararat). It contained over 200 furnaces,

producing an assortment of vases, knives, spearheads, rings, bracelets, etc.

The Metsamor craftsmen wore mouth-filters and gloves while they laboured and

fashioned their wares of copper, lead, zinc, iron, gold, tin, manganese and

fourteen kinds of bronze. The smelters also produced an assortment of metal

paints, ceramics and glass. But the most out-of-place discovery was several

pairs of tweezers made of steel, taken from layers dating back before the

first millennium BC. The steel was later found to be of exceptionally high

grade, and the discovery was verified by scientific organizations in the

Soviet Union, the United States, Britain, France and Germany. (9).

(Click here for more about Metsamor)

Metallurgy in Africa.

Egypt: The Great pyramid of Giza: Iron plate found in

'star-passage'. (See below)

Tanzania

- 1,500 AD - The discovery

of steel-smelting ovens (producing carbon steel), achieving temperatures of

1,800 centigrade (3)

|

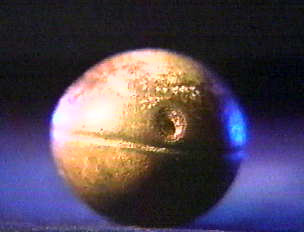

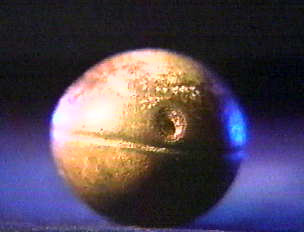

The South African spheres

- 'The Klerksdorp Spheres':

Quote from (1) - 'Over the past several decades, South African miners

have found hundreds of metallic

spheres, at least one of which has three parallel grooves running around its

equator. The spheres are of two types - "one of solid bluish metal with

white flecks, and another which is a hollow ball filled with a white spongy

centre" (Jimison, 1982). The sphere

in the photos (below), was found in a Precambrian mineral deposit, making it

an unlikely 4,500 Million years years old. Some of the spheres

can be seen in the Museum at Klerksdorp, South Africa. (3)

At least 200 have been found, and extracted out of deep

rock at the Wonderstone Silver Mine in South Africa, averaging 1-4 inches in

diam. and composed of a nickel-steel alloy that doesn't occur naturally.

Some have a thin shell about a quarter inch thick, when broken open are

filled with a strange spongy material that disintegrates into dust upon

contact with air.

(More about the 'Klerksdorp Spheres') |

Metallurgy in the America's.

Peru - Pre Inca

ornaments and other objects made of Platinum have been discovered. (The

Melting Point of platinum is 1,755 degrees Celcius).

(9)

( More about ancient Peru)

Metallurgy in Asia.

China

- An aluminium belt fastener with open-work

ornamentation was found in the grave of General Chou Chu of the Chin

dynasty, who lived from 256-316 AD. The fastener was examined by the

Institute of Applied Physics of the Chinese academy of Sciences and by the

Dubai Polytechnic. The process of extracting aluminium from Bauxite today

involves the use of a 'Reverbier' oven, refraction chamber and regenerator,

as well as electrolysis and temperatures exceeding 950�

Celcius. (9)

Meteoric Iron - Also recorded from China are 'two

puzzling ancient iron axes' dated c. 1000 B.C. - almost half a millennium

before iron working began in China - which were finally identified as

meteoric nickel-iron. In ancient Mexico, Indian ploughshares were made of

meteoric iron, and the Greenland Eskimos had a long tradition of using

meteoric iron for harpoons.

(2)

|

Metal in the Great Pyramid: |

There were several metal items found in the Great

pyramid of Ghiza:

The

Iron Plate

- On Friday, 26 May 1837, after a few days of blasting and clearing, J.

R. Hill (working for Vyse), discovered a flat iron plate about 26 cm

(10.2") long, 8.6 cm (3.4") wide, with a thickness ranging from .4 cm

(.2") to nearly zero, from a joint in the masonry at the point where the

southern airshaft from the King's chamber exits the pyramid. Engineers

agree that this plate was left in the joint during the building of the

pyramid and could not have been inserted afterwards. Colonel Vyse sent

the plate to the British Museum. The

Iron Plate

- On Friday, 26 May 1837, after a few days of blasting and clearing, J.

R. Hill (working for Vyse), discovered a flat iron plate about 26 cm

(10.2") long, 8.6 cm (3.4") wide, with a thickness ranging from .4 cm

(.2") to nearly zero, from a joint in the masonry at the point where the

southern airshaft from the King's chamber exits the pyramid. Engineers

agree that this plate was left in the joint during the building of the

pyramid and could not have been inserted afterwards. Colonel Vyse sent

the plate to the British Museum.

Hill affirmed that his find was legitimate:

This is to certify,

that the piece of iron found by me near the mouth of the air-passage,

in the southern side of the Great Pyramid at Gizeh, on Friday, May

26th, was taken out by me from an inner joint, after having removed by

blasting the two outer tiers of the stones of the present surface of

the Pyramid; and that no joint or opening of any sort was connected

with the above-mentioned joint, by which the iron could have been

placed in it after the original building of the Pyramid.

I also shewed the exact point to Mr. Perring, on

Saturday, June 24th.

(Vyse, Pyramids of Gizeh,

I, p. 276)

The plate was examined by the famous Sir Flinders Petrie

in 1881. He felt it was genuine and stated that...

"no reasonable doubt can therefore exist about

its being a really genuine piece".

Extract from Petrie -

That sheet iron was employed we know, from the

fragment found by Howard Vyse in the masonry of the south air channel;

and though some doubt has been thrown on the piece, merely from its

rarity, yet the vouchers for it are very precise; and it has a cast of

a nummulite on the rust of it, proving it to have been buried for ages

beside a block of nummulitic limestone, and therefore to be certainly

ancient. No reasonable doubt can therefore exist about its being

really a genuine piece used by the Pyramid masons; and probably such

pieces were required to prevent crowbars biting into the stones, and

to ease the action of the rollers.

H.R. Hall wrote of

the plate in "Note on the Early Use of Iron in Egypt" (Man 3, 1903):

Now that

Professor Petrie has discovered iron in deposits of VIth Dynasty date

at

Abydos, the contentions of those Egyptologists who have

always maintained that iron was known to the Egyptians from the

earliest times must be acknowledged to be correct. The fact that iron

was known to, and used by, the Egyptians over 2,000 years before it

came into use in Europe is very remarkable, and it is hard to square

with current theories, but it is a fact. Professor Petrie's find is a

lump of worked (?) iron, perhaps a wedge, which is rusted on to a bent

piece of copper...

This is the third find of iron which can be attributed

to the Old Kingdom. In 1837 a fragment of wrought-iron was discovered

in an inner joint of the stone blocks in one of the air-passages which

pass upwards from the interior of the Great Pyramid to the outer air [Vyse,

Pyramids of Gizeh, I., 276; Beck, Geschichte des Eisens, I., 85]. This

is now in the British Museum, Egyptian Department, No. 2433 (3rd

Egyptian Room, Case K, 29). In 1882 Professor Maspero found iron in

the pyramid of a Vth Dynasty king at Ab�s�r. Professor Petrie has now

found iron in a VIth Dynasty deposit at Abydos... The presumption now

is that the iron fragments from Ab�s�r and from the Great Pyramid are

of a Vth and IVth Dynasty date respectively. The G�za fragment will be

about 150 years older than the piece from Abydos. (pp. 147-49)

Tests were actually made in the British Museum

Laboratory, and since it seems desirable that the matter should be

cleared up, Dr. J.H. Plenderleith reported the following:

The Pyramid piece was found to consist 'of a thin

film of metallic iron with a more or less thick coating of its

oxides.' Samples were examined and 'no nickel could be detected.' This

was in November 1926; in April 1932 it was examined again, and the

results 'completely bear out the findings of the previous analytical

report as regards to the absence of nickel;' separate tests were

applied to the exterior scale and to the surface of the metallic iron

itself, and nowhere could nickel be detected. As Dr. Plenderleith was

advised that 'all known meteoric iron contains some nickel, about 4-30

per cent,' he considered it 'unnecessary to go any further in the

matter of chemical investigation.' The account of the result quoted

from Man (cf. also Dr. Rickard's Man and Metals 1932, II, 834) seems

therefore to have mislead Mr Wainwright.

The pyramid piece contains no detectable 'traces' of nickel.

In 1989, an analysis of the iron plate was made by El

Sayed El Gayar and M.P. Jones, published in their article "Metallurgical

investigation of an iron plate found in 1837 in the Great Pyramid at

Gizeh, Egypt" (Journal of Historical Metallurgy Society, Vol. 23

No. 2, 1989, pp. 75-83). El Gayar and Jones, using a hacksaw, carefully

cut off a small corner of the plate for analysis. This fragment was

triangular in shape with an area of 1 cm and a weight of 1.7g. After

again determining that the iron contained "only a trace of nickel",

thus confirming a terrestrial origin (p. 81), the authors found that the

plate consists of numerous laminates of wrought iron and that these

laminates have been inexpertly welded together by hammering. The various

layers differ from each other in their grain sizes, carbon contents, the

nature of their non-metallic inclusions, and in their thicknesses...

None of the iron layers contains siliceous, slaggy inclusions.

Furthermore, none of the other phases within the iron laminates shows

any metallic copper globules, nor do they show more than small

traces of the element copper. These features suggest that the

Gizeh iron plate had not been produced as a by-product of copper

smelting operations. The outer layers of the iron have been badly

corroded and now exist as complex banded iron oxides. Small, but

significant, proportions of gold were found in one of the oxidised

layers and it is thought possible that the plate may, originally, have

been gold-plated.

Drs. Jones and Gayer concluded the following: "It is

concluded, on the basis of the present investigation, that the iron

plate is very ancient. Furthermore, the metallurgical evidence supports

the archaeological evidence which suggests that the plate was

incorporated within the pyramid at the time that structure was being

built".

A more recent analysis of the plate, however, has cast

doubt on the findings and conclusions of the study by El Gayar and

Jones. In their article "Gizeh Iron Revisited" (Journal of the

Historical Metallurgy Society, Vol. 27 No. 2, 1993, pp. 57-59), Paul

Craddock and Janet Lang of the British Museum reported that they were at

first unable to obtain the section cut by El Gayar and Jones,

consequently the initial study was confined to the larger portion of the

plate. A new section was cut adjacent to the original section, and it

was examined under a scanning electron microscope both at the British

Museum and independently at the Ancient Monuments Laboratory, English

Heritage (the work was carried out there by Dr. G. McDonnell). It was

also analyzed by x-ray fluorescence. Surprisingly, no gold was detected

in the metal or in the corrosion. Craddock and Lang further wrote:

Since the last

report the original section has been returned to the Museum and we

have been able to carry out a thorough investigation. Once again we

must report that despite extensive searches no trace of gold could be

detected, and it is our firm opinion that the original report of gold

is incorrect.

The authors agreed with El Gayar and Jones regarding the

structure of the iron plate, but they did not agree on the

interpretation. They conclude the following - 'The structure of the

plate is consistent with iron-making in the post-medieval Islamic era'.

Comment - The plate has been determined of terrestrial

origin. It was declared of ancient origin because of the numulite

imprints in it. This was a specific observation, as was the

determination that it could not have fallen in at a later date. Other

contemporary findings of iron support the idea that this could at least

be genuine.

The royal funerary Pyramid Text �907 reads: The doors of

bA-kA [an unknown region of the sky] which is in the firmament are

opened for me, the doors of iron which are in the starry sky are thrown

open for me, and I go through them ...

And finally, this extract from Miracle in Stone.

(It does seem strange that none of the learned professors above ever

noticed it):

'The

Siniatic Mountains and hills are known to be full of

iron of the most excellent kind. A Mr. Hartland some years ago,

established himself in that region for mining purposes, and there,

near Surabit-el-Khadem ,and not far from Wady Meghara, he found, not

traces merely, but colossal remains, of iron works and furnaces,

belonging to the earliest kings of ancient Egypt, and on a scale so

vast as to be testified to by almost mountainous heaps of genuine iron

slag and veritable iron furnace refuse (see proceedings Soc. Antiq.,

Vol V, 2d series, June 1873). Nay. What is

more remarkable, here also, is a tablet containing the cartouches of

Shufu (Cheops) and Nem-Shufu, the same as the quarry-marks discovered

by Colonel Howard Vyse on the hidden stones in the Great Pyramid!

These records are engraved in a soffit in the face of the natural

rock, where they directly overlook the scene of the furnaces. They

begin with the name of Soris, the immediate predecessor to Cheops,

under whom the Egyptians seem to have been put through an

apprenticeship of working in iron. One of Egypt's ancient kings also

appears on the monuments with a name which means "A lover of Iron".'

Apart from the obvious implications of an Iron works with

the cartouches of fourth dynasty kings on it, it is interesting that the

name 'Soris' is mentioned, as this seems to confirm Manetho's

chronology. It also implies that Iron was understood and forged

before the pyramid was built. Just how big is this mine and where is

the Iron?

There

is also some Copper in the Great pyramid.

Queens Northern Shaft.

Queens Southern Shaft.

Both the shafts leading from the queens chamber have

copper 'handles' at their ends. Their significance is yet to be

determined but their presence in such a hidden and inaccessible internal

part of the structure is an absolute proof that metal-working was

present at the time of the 4th dynasty.

(More about the Great pyramid)

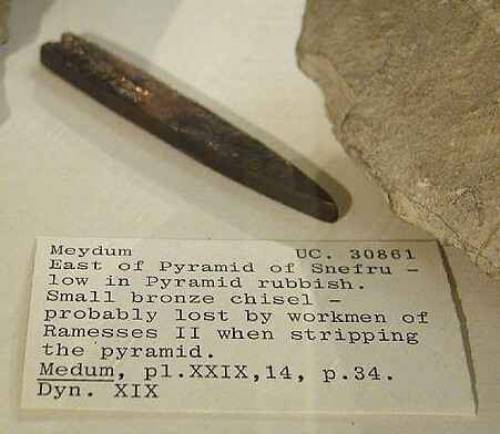

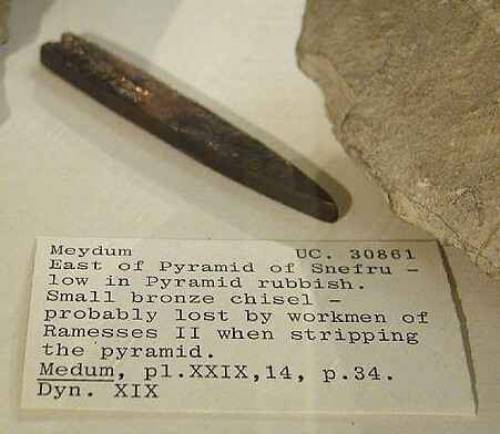

Bronze Chisel from the Cairo Museum. c. 2,000 BC.

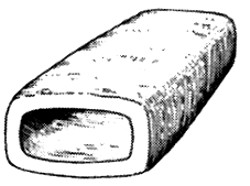

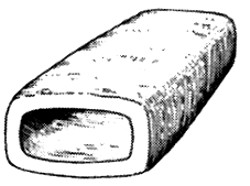

The metallic �tubes� from Saint-Jean

de Livet (France)

In 1968, Y Druet and

H Salfati claimed to have discovered a number of semi-ovoid metallic

tubes they believed to be artificial in Cretaceous (Aptian) chalk at a

quarry in St-Jean de Livet (France), which they announced in a letter to

the editors of Plan�te, a French magazine devoted to

unsolved mysteries. The tubes were shaped identically, but their sizes

varied between 30 and 90 mm in length, and 10 and 40 mm in width.

According to the authors of the letter (dated 30 September 1968), the

objects were currently being studied by the Geomorphology Laboratory of

the Universit� de Caen, but nothing further seems to be known about

them. In 1968, Y Druet and

H Salfati claimed to have discovered a number of semi-ovoid metallic

tubes they believed to be artificial in Cretaceous (Aptian) chalk at a

quarry in St-Jean de Livet (France), which they announced in a letter to

the editors of Plan�te, a French magazine devoted to

unsolved mysteries. The tubes were shaped identically, but their sizes

varied between 30 and 90 mm in length, and 10 and 40 mm in width.

According to the authors of the letter (dated 30 September 1968), the

objects were currently being studied by the Geomorphology Laboratory of

the Universit� de Caen, but nothing further seems to be known about

them.

|

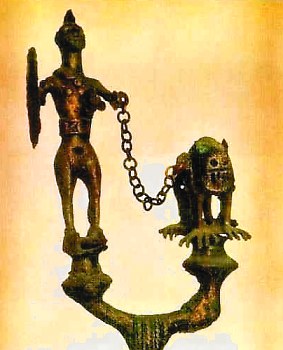

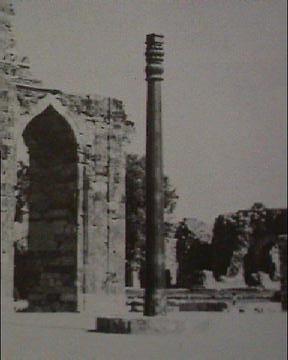

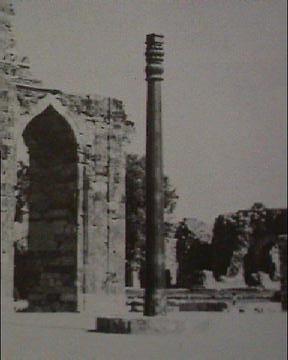

India - The Iron Pillar of Delhi (Photo, left), in the courtyard of

Qutub Minar in Delhi. It is

a column of Cast Iron weighing approx. 6 tons and standing 23ft 8 inches

high, with a diameter of 16inches. The column had stood in the temple of

Mutra, capped with 'Garuda', an image of a bird incarnation of the God

Vishnu. Muslim invaders later destroyed the 'Garuda' and tore the column

from its original setting, re-erecting it in Delhi in the 11th century AD.

It bears an inscription of an epitaph to King Chandragupta II, who died in

413AD. The bar shows some weathering, but unusually little rust.

(9)

(Prehistoric India)

Der Eiserne Mann

The 'Iron Man

of Kottenforst', Bonn

The pillar has the appearance of a squared metal bar, about 1.47 m above ground and approximately 2.7 m below

ground. It was first mentioned in a document in 1625 as part of the border

line between Alfter and Heimerzheim along the Roman aqueduct .

Associated

with the Iron man are an ancient stone walkway and the remains of an

aqueduct which runs straight towards the pillar. The 'Iron-man' also

shows very little sign of rust, and its actual origin is unknown.

Although the origin of this pillar is unknown, the technique and

the style point to a date of manufacture in the late Middle

Ages. (4)

(Prehistoric

Germany)

Other Eigmatic Metal Discoveries:

1968 -

Semi-ovoid metallic

tubes of identical

shape but varying size found in Cretaceous chalk. The chalk-bed was exposed

in a quarry at St. Jean de Livet, France, and is estimated to be at least 65

million years old.

(3)

Mechanically manufactured gold thread

found in sandstone rock, Rutherford-Mills, England. It was found embedded in

naked rock, at a depth of about 8 feet. 60m yrs. (The Times, June 22nd 1844)

(8).

1881

- An 'iron nail'

from gold bearing quartzite from Kingoodie, Nr Dundee, 387m yrs. (The Times,

Dec 1881).

1891 -

Morrisonville, Illinois, USA. An 8 carrot (alloy), gold chain found

embedded in coal by Mrs S. W. Culp. As she undertook to take the chain from

the coal, the middle of the chain became loosened while each end remained

fastened. (estimated at 260-232 million years old).

(9).

1942

- Iron chain

still embedded in sandstone, California. Extant photo but object lost.

(Other Examples of Oopart's)

Copper

Mining

in Rudna Glava, Serbia (Vinca Culture):

The early Neolithic

Vinca mine of Rudna Glava near Majdanpek (5,000 B.C.) is an

example of the oldest known technology of copper working. The developed

skills of the Rudna Glava miners are indicated by the ore-emptied shafts no less than 20m deep.

Stone mallets, made from river stones

of volcanic rock, gives evidence of the higher

specialization of primitive tools for different and

various productive purposes. As for the chopping of the pieces

different types of wedges were used, while the tools made from

deer horns were used for gathering the ore already chopped.

When an ore vein was

discovered, the access platform was built round its flooding

canal. Afterwards the hard ore mass was broken into pieces by

circular hits with stone mallets, hanged either on a rope or leather

belt. In the depths, the technique of heating then cooling

suddenly was

used. Large ceramic dishes were used for

pouring the water over the hot ore blocks. Cracked blocks were

further smashed and broken into pieces.

The ore obtained was

taken to the surface in bags, and it was distributed to

the settlements near by. Further metallurgic processes are

considered to be a part of technological circle of handworks in

that early period of metal usage.

-

(Full Article:

http://www.muzej-mpek.org.yu/e_rglava.htm)

-

-

Mining for copper in Wales: (Extract...)

In July 1993, a Research Steering

Committee was set up to co-ordinate research on the Great Orme,

North Wales, a precipitous headland rising 220 metres above the

Irish Sea. The extensive copper mineralization hosted by this

isolated outcrop of Carboniferous limestone was exploited in

prehistory.

In their search for copper, the

prehistoric miners produced a labyrinthine complex of rifts and

galleries within the headland, which date primarily to the Bronze

Age (the second millennium BC) and cover an area of at least 240

metres by 130 metres, with vertical depths of up to 70m (Lewis

1997: 106, 158). The extent and unparalleled degree of

preservation of these workings render the Great Orme copper mine

one of the most important sites in Britain and Europe for research

into prehistoric copper metal production.

(Article:

http://www.assemblage.group.shef.ac.uk/4/4wager.html )

Mining in Ancient Britain:

(Extract...)

For more than half

a century archaeologists have grappled with the enigma of

Britain's first use of metals. It appears to have taken the art of

metallurgy more than 2,000 years to travel from the ancient Near

East and Balkans to Britain, and its dramatic arrival in about

2500 BC prompted early scholars to suggest direct contact between

Britain and the great metal-using civilisations of the

Mediterranean. The images evoked were of roaming metal prospectors

searching savage lands for raw materials. The reality may be more

prosaic, but is no less interesting.

In fact, the long

history of metallurgy was not just a Mediterranean affair. For its

origins we have to look several thousand years before the Castell

Coch artefacts were deposited in their shallow sanctuary. The very

earliest copper objects come from settlements and graves of the

late 8th/early 7th millennium BC in Mesopotamia and Anatolia, and

these are thought to be the products of rare outcrops of copper

metal (not copper ore) found in some parts of this copper-rich

area.

The momentous

discovery of smelting came later, in the mid-5th millennium,

seemingly independently in Anatolia, Mesopotamia and the Balkans.

By this time copper miners were hard at work at places such as

Aibunar in Bulgaria and Rudna Glava in Serbia, where rich veins of

copper oxide and carbonate minerals were being emptied to make

what must have seemed an entirely new kind of material. Hard

enough to sharpen to a cutting edge, yet tough enough not to

shatter. Infinitely re-meltable and re-useable.

After perhaps a

thousand years of Balkan copper production, the deposition of

copper in hoards and graves faded away. The technology was not

lost though. As dramatically as it appeared to decline, metallurgy

was back, but this time in a different location and with a new

sort of metal. In the mid-4th millennium, arsenical copper was now

taking centre stage with a new focus on Alpine and sub-Alpine

Europe. A similar copper-arsenic alloy was developed in the old

copper-producing centres of the Near East, although there the

transition took place without the production hiatus apparently

experienced in Europe.

Exploitation of the

rich Alpine copper required the development of a new technology.

Unlike the Balkan ores, the Alpine deposits were mostly of copper

sulphide minerals. Unusable as mined, these had to be roasted

before smelting to convert the sulphide minerals to the oxides

that would have been familiar to the Balkan smelters. In practice,

lumps of sulphide ore were placed on a hot wood fire and stirred

round, to introduce plenty of oxygen and convert the ore to copper

oxide. The oxide ore was then smelted in an enclosed furnace

heated by charcoal with as little oxygen as possible to reduce the

ore to metal. Such roasting beds and smelting furnaces dating from

the later Bronze Age have been found in the Mitterberg region

south of Salzburg.

Recent research

suggests that early metal workers knew exactly what they were

doing in using these ores. A significant addition of arsenic to

copper produces better mechanical properties, and higher levels

produce a metal of striking silvery appearance. Artefacts with

higher levels tended to be `high status' objects such as knives

and daggers, while everyday tools, such as the 4th millennium BC

Iceman's axe, contained less. The proportion of arsenic in

artefacts ranges from less than 1 to 7 per cent - never more than

that - while ores can contain up to 30 per cent, suggesting that

arsenic quantities were being controlled.

The evidence for

such mixing comes from slightly later periods, but might apply

equally to the 4th millennium. At the mine site at Ross Island in

Ireland, for example, dating from the mid-3rd millennium, the ores

are varied, containing anything from a few to about 30 per cent

arsenic. However, the metal produced was much more consistent,

suggesting that the ores were mixed. Later still, in the 2nd

millennium, the Great Orme mines in North Wales produced perhaps

hundreds of tonnes of copper at a time when most artefacts

contained some degree of arsenic, and yet the Great Orme ores

contained no arsenic whatsoever. The Great Orme metal was clearly

not used without some degree of adaptation.

Whatever the truth

of central Europe's arsenical copper in the 4th millennium,

Britain remained literally in the Stone Age. It would be a

thousand years before the island periphery of north-western Europe

was to experience metallurgy at all. And yet when it came, the

metals revolution took off with explosive technological pace.

Within a few hundred years not only was a Continental-style

arsenical copper industry thriving here, but by about 2000 BC the

harder, tougher alloy of copper and tin known as bronze had also

been invented. It replaced arsenical copper across Europe and

dominated the European metals scene until the coming of iron more

than 1,000 years later.

It is perhaps not

strictly true to say that bronze was invented in Britain. The very

earliest combination of tin and copper is found in Anatolia, but

Near Eastern bronze contained less tin, in less standardised

quantities, than was found in British bronze. Put simply, it was

inferior bronze. In Britain, bronze was produced from the outset

with an almost standard composition of 8 to 12 per cent tin,

ensuring the optimum mix of qualities. For archaeologists the

rapid establishment and spectacular success of metallurgy in the

British Early Bronze Age, from 2500-2000 BC, is something of a

quandary. How did metallurgy arrive in an apparently advanced

state? Who brought it and why did it take off here so well?

In fact, the region

where early tools and weapons suddenly appear in large numbers is

south-west Ireland, predominantly in the form of simple `flat'

axes. Wherever it was made and traded, more of it was left behind

in the rugged Atlantic coastal landscape of Munster than anywhere

else. This Irish metal was not inferior stuff either. What was

being made and deposited was not the simple copper of the earliest

European metallurgy, but arsenical copper, the superior material

pioneered in Alpine Europe and, by this time, also commonplace

throughout the Mediterranean as far west as Spain and Portugal.

So how did this

advanced technology suddenly come to Ireland, and why? Who were

these metal makers? To a previous generation of archaeologists

such developments could only be explained by the invasion and

settlement of new, technologically advanced, people. If not Greeks

prospecting for precious ores, perhaps Iberian settlers made their

way north along the Atlantic coast seeking out sources of the

arsenic-bearing copper ores with which they were familiar.

This notion of a

mass movement of people, even an invasion, found support elsewhere

in the archaeological record. The arrival of metallurgy was not

the only big change taking place in the middle of the 3rd

millennium, but the period also saw the appearance of beaker

pottery in the British Isles. These highly distinctive vessels,

often buried with the dead, were widespread in central Europe and

Iberia before they were used in Ireland. Was there a link?

(Article:

http://www.britarch.ac.uk/BA/ba56/ba56feat.html )

Egyptian copper mining:

(Extract...) Copper was the first metal to see

extensive use in Egypt. Copper tools, weapons, and ornaments are

found beginning approximately 4000 BCE. Conditions for miners were

described as �wretched,� and for most of the years of Egyptian

history, the work seems to have been done by teams of slaves.

Smelting to extract metal from the ore was almost

always done on-site, no matter what was being mined. Copper ore

was extracted and broken into small pieces and mixed with charcoal

fuel in a fire on the ground or in a shallow pit. This method

produced temperatures of between 700 and 800 degrees Celsius,

enough to separate the metal from the rock, but not hot enough to

reduce it to a truly molten state.

Estimates made from slag heaps

found at these copper mining operations indicate that an average

of five tons of copper were produced annually in Egypt during the

Bronze Age, which was not enough to supply the kingdom with its

metal needs, necessitating importation of copper as well as tin

for Egypt's bronze production. This harder, easier to cast metal

eclipsed copper as the major material for tools in Egypt after its

introduction from western Asia.

Egypt's history as a metal-using

culture extends deep into the past. Copper and gold tools and

ornaments date back to the Pre-Dynastic period and its craftsmen

have produced a myriad of beautiful treasures and practical tools

during Egypt's time as a power and a living culture. Although

Egypt was not the originator of metalworking, the exploitation of

the mineral resources under its control assisted in its rise to

power and craftsmanship.

(Article:

http://www.mnsu.edu/emuseum/prehistory/egypt/dailylife/mining.htm

)

|

In 1968, Y Druet and

H Salfati claimed to have discovered a number of semi-ovoid metallic

tubes they believed to be artificial in Cretaceous (Aptian) chalk at a

quarry in St-Jean de Livet (France), which they announced in a letter to

the editors of Plan�te, a French magazine devoted to

unsolved mysteries. The tubes were shaped identically, but their sizes

varied between 30 and 90 mm in length, and 10 and 40 mm in width.

According to the authors of the letter (dated 30 September 1968), the

objects were currently being studied by the Geomorphology Laboratory of

the Universit� de Caen, but nothing further seems to be known about

them.

In 1968, Y Druet and

H Salfati claimed to have discovered a number of semi-ovoid metallic

tubes they believed to be artificial in Cretaceous (Aptian) chalk at a

quarry in St-Jean de Livet (France), which they announced in a letter to

the editors of Plan�te, a French magazine devoted to

unsolved mysteries. The tubes were shaped identically, but their sizes

varied between 30 and 90 mm in length, and 10 and 40 mm in width.

According to the authors of the letter (dated 30 September 1968), the

objects were currently being studied by the Geomorphology Laboratory of

the Universit� de Caen, but nothing further seems to be known about

them.